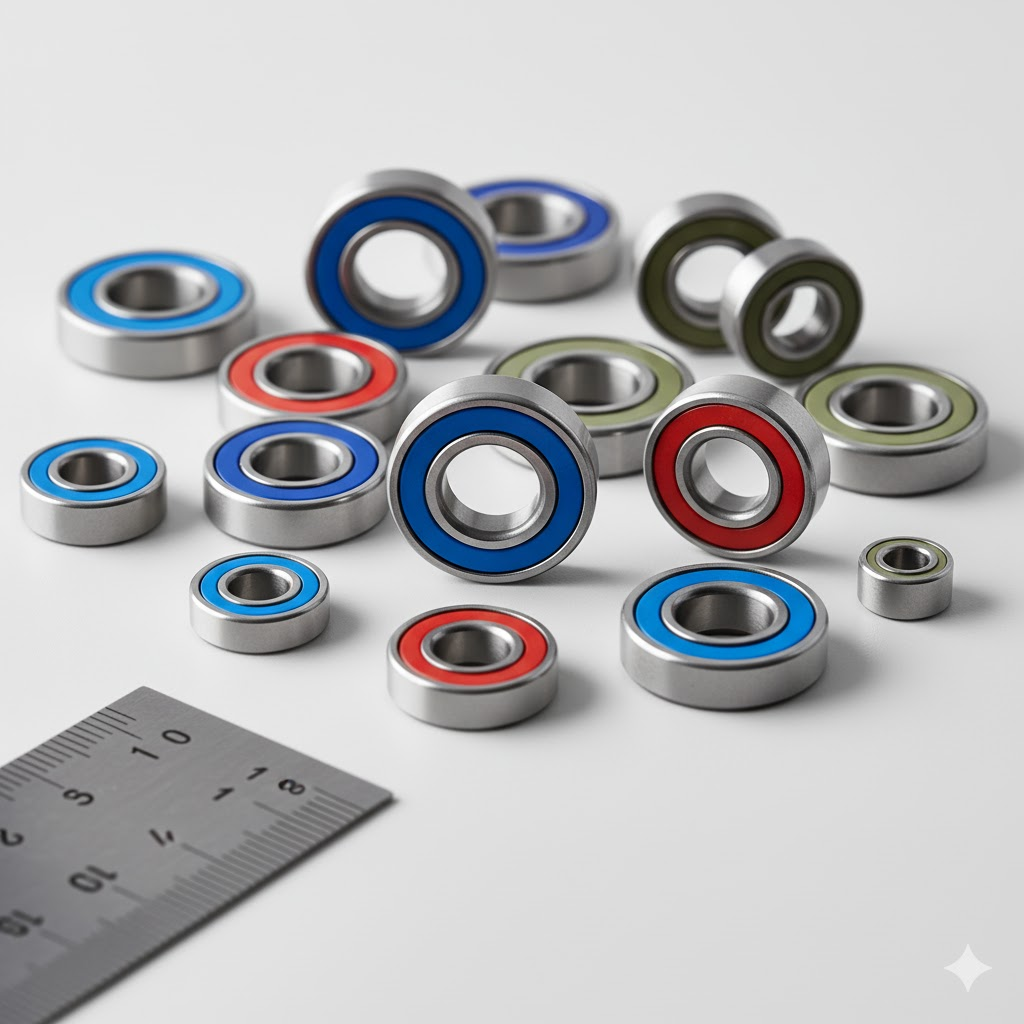

Miniature bearings

People sometimes refer to miniature bearings as instrument bearings or micro bearings. Their compact size and exceptional performance characteristics make them essential components in many industries. They are used in applications as varied as gyros, anemometers, flow meters, miniature gearboxes, small motors and radio controlled models.

Ball bearings are usually made of chrome steel, which is a great choice because of its strength, low-noise characteristics, and affordability. Our chrome steel range of mini ball bearings are available with a flange on the outer ring as shown in Products Variants below.

Request a Quote

Take the next step to forging your path to success. Request a quote from our team.

All Industries

Advantages of Miniature Bearings

Miniature bearings are highly engineered precision components that play a crucial role in various applications where size and performance are critical. Their main advantages include: Space-Saving Design (Compact Size): They are specifically designed to fit into applications with extremely limited space, enabling smaller, more innovative, and efficient product designs. Example: Used in medical devices, dental drills, and small robotics. Low Friction and High Efficiency: They are engineered to minimize friction between moving parts, leading to reduced energy loss and increased mechanical efficiency. This also contributes to lower heat generation and longer equipment life. High Precision and Accuracy: Miniature bearings are manufactured to high-precision tolerances (often ABEC grades), ensuring accurate, precise, and smooth rotational or linear movement. This is essential for instrumentation and high-tech applications. Ability to Handle High Speeds: Due to their design and precision manufacturing, many types of miniature bearings are capable of operating reliably at very high rotational speeds with low noise and vibration.

Operating condition considerations for miniature chrome steel bearings

Chrome steel bearings can handle temperatures up to 120°C when used continuously, with a steel retainer and proper lubrication. They can also be used up to 150°C intermittently. At temperatures above a certain level, the strength of chrome steel bearings decreases and they experience more of a size change compared to stainless steel. Chrome steel is not ideal for use in corrosive environments, as it does not have corrosion resistance. To protect against moisture, miniature chrome steel bearings are coated with a preventive oil. We do not suggest using chrome steel ball bearings without lubrication (dry) because they are prone to rusting.

This can even happen when they are not in use or while they are in transit due to condensation forming inside the packaging. You cannot apply the protective oil to a dry bearing. The oil would potentially find its way inside the bearing making it no longer “dry”.

Compact Size

They have a small outer diameter (often under $20 \text{mm}$) allowing for space-saving and miniaturization in precision equipment.

High Speed Capability

Designed for high precision, they can operate efficiently at very high rotational speeds.

High Precision & Low Noise

They are manufactured to high tolerance standards (e.g., P5 or better), ensuring smooth operation and minimal noise/vibration.

Versatility in Harsh Environments

Available in specialized materials to offer good resistance to heat, corrosion, and wear.

Quality Miniature bearings

Open bearings are supplied with a light oil lubrication. Shielded or sealed bearings are usually supplied with grease lubrication. However, shielded bearings can be offered with instrument oil for low speed, low friction applications. Thanks to our in-house relubrication facility, these miniature bearings can be offered with customer specified oils, greases or dry lubricants.

Our Standard Forging Timeline

Scroll through to learn more about how our forging manufacturing process works:

Step 1/7

SolidWorks 3-D Modelling & Closed-Die Concept

LungChau Forge engineers turn your finished or semi-finished drawing into a validated 3-D SolidWorks model and multi-directional die layout within days.

Step 2/7

Die-Steel Machining on CNC Centres

We purchase premium die steel and machine the upper, lower and side rams to micron tolerances in our own machining centre.

Step 3/7

Certified Material Procurement

Alloys are ordered to the exact grade and size jointly signed off on the billet drawing, with full mill test certificates.

Step 4/7

Incoming Inspection & Precision Cutting

Bars are verified, then bandsaw or sheared into weight-controlled billets ready for heating.

Step 5/7

Green Heating – Induction or Natural-Gas Furnace

Billets are heated uniformly in an eco-friendly natural-gas or medium-frequency induction furnace to the optimal forging window.

Step 6/7

Multi-Ram Closed-Die Forging

Hot billets are shuttled within seconds to friction-screw or hydraulic presses where multi-directional rams form complex net-shape parts in one strike.

Step 7/7

UT / MT Non-Destructive Testing & Release

Every lot can be ultrasonically or magnetic-particle inspected to ASTM, EN or customer standards, ensuring defect-free delivery from LungChau Forge.